It is easy to imagine how industrial companies harnessing the power of the massive computing abilities created by the leading technology companies are going to dominate their respective industries in the decade to come. Industrial organizations have amassed years of data in their ERP systems while becoming adept at collecting real-time operational data from sensors, CNC equipment, and Auto-ID technologies.

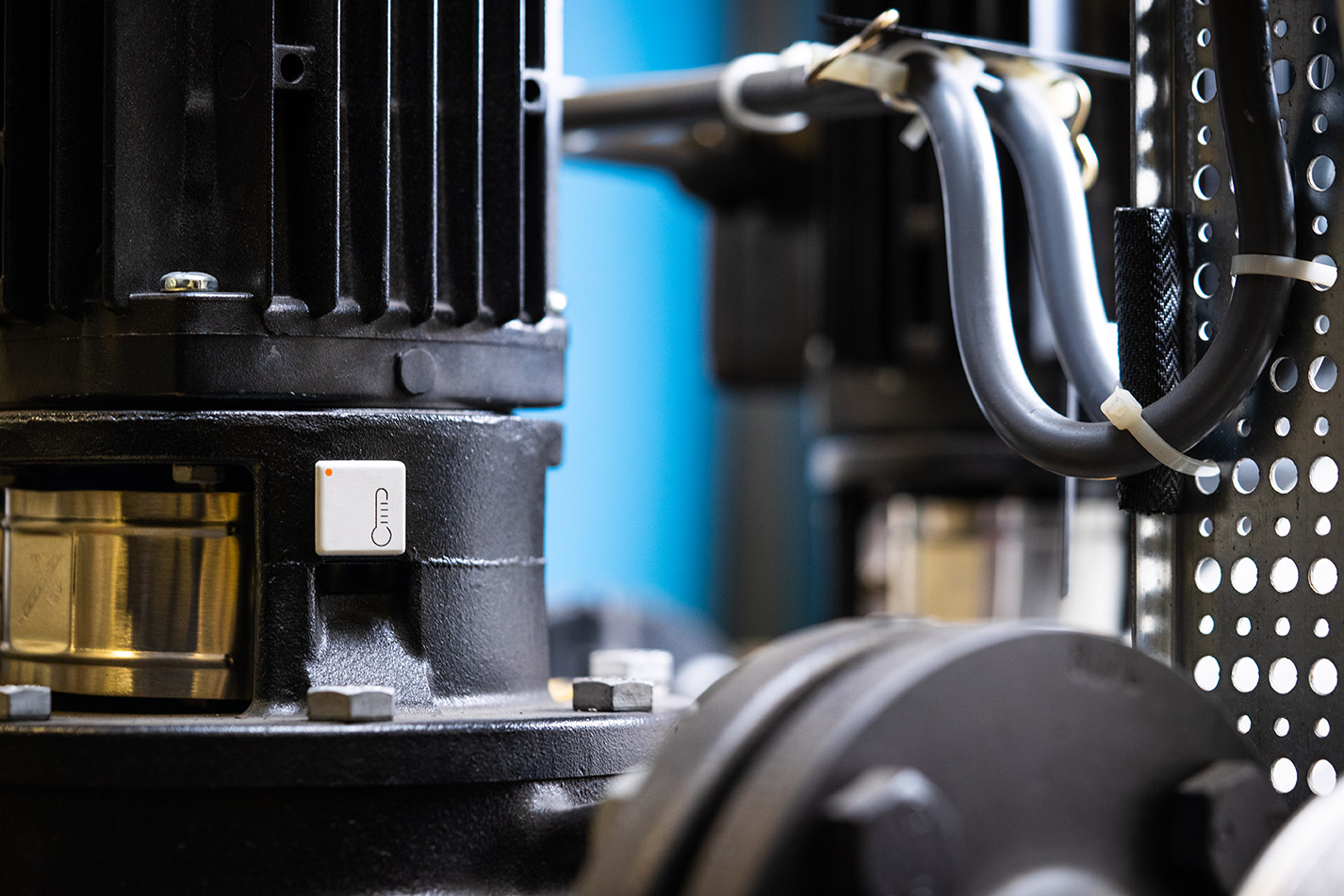

With every layer of new information, there is a greater level of resolution that drives logistics efficiency, production optimizations, and favorable outcomes. When creating a Digital Twin Solution, scalability and synchronization are important aspects to consider.

Add clarity to the details you collect. Bring context to the data you connect. Scale smart. Here’s how.